External Author – JJ Lay

Note that this tutorial is not my own work, but was developed by the adorable JJ Lay and is hosted here for convenience.

Landing Gear

This is more important than you think it is.

We talked about doing a drop test all year of just about a 1ft. and now we have come to see that it is important to do so. So here are a few things I have learned over my time. With a few different materials that should be talked about.

TIPS/TRICKS:

- Make sure the landing gear is IN FRONT of the center of gravity (with at least some margin of error). If not, then there will be a moment created with the propellor and the plane will nosedive… on the ground… and not take off…

- Make sure the landing gear is TALL enough so the desired propellor does not impact the ground when the plane is parallel with the ground.

- Make sure the rear landing gear is also off the ground enough to ensure the tail has wind able to pass on both sides of it.

- If you plan on flying in grass, make sure the landing gear is a little extra tall just wanted to put a double-check in there.

- Make sure to do a DROP TEST of at least a foot, no matter how good a pilot is, there could always be a gust of wind that creates an ill-timed landing. If the landing gear breaks, pops off the plane, or breaks part of the plane adjust as needed.

- The ability to absorb impacts is crucial to the landing gear. The more impact the landing gear can absorb and withstand the better.

- The landing gear should be relatively easy to re-fabricate, so it should be taking the impact all the way until destruction rather than the plane.

- Finally, make sure the WHEELS are big enough for the surface you are running on, i.e. We used large 3” foam wheels for grassy takeoffs, and smaller thinner wheels for pavement, etc.

- If you want the plane to have a takeoff angle of attack, it is helpful to use the CAD model to do the math, knowing the propeller size and the location of the front landing gear makes it simple to do quick trigonometry to find the size of the rear.

- Bearings are your friends if you can get them to work. The attachment of wheels to landing gear needs to be sturdy, but also a 3d printer part with a big enough hole for a nut and bolt work perfectly as well.

- The attachment to the plane is a huge thing, this year it had to be easily removable, so the attachment mechanism was sub-par. If you can attach the landing gear rigidly to the plane it is better than it falling off every attempt at landing and hurting the plane.

- There are a ton of resources and RC hobbyists out there that know way more than I ever would, be sure to use the internet to your advantage!

FABRICATION:

Wood landing gear:

- No. If you go to Google and look up wood landing gear there is no such thing. Do not make landing gear out of wood unless you do not want it to work or be a one-use thing.

Carbon fiber landing gear:

- Do not try to make it yourself unless you have professional experience, we did not but we did it anyway. They broke on impact during our first attempt, and it was because we did not ensure there was resin everywhere.

- If you are to use this type, we used an already made one from a company and it worked wonders. It never broke and only detached due to our poor attachment mechanism (see tips and tricks above).

Aluminum:

- Now we are talking, Aluminum is probably the best to work with because of its ability to bend to absorb impacts, ease to work with, and you can rigidly attach to it (aka drill nicely into it).

- If you google RC aircraft landing gear, there is a ton of different examples of how aluminum is used. From tiny wires, to full on bars that attach it is probably the most versatile material to use.

- When starting to build the plane use aluminum since it is a quick fix and can absorb impacts once everything is nailed down and works out then maybe jump back to carbon fiber.

In conclusion, there are a lot of resources online (including Jordan’s) to help out with making landing gear. Use them to your advantage! It may be worth it to allow a little extra weight for it for the plane not to break apart on every impact.

Wing & Tail

Congratulations, you have looked at the competition missions, done math from those missions, looked at materials, looked online for ideas, picked out a wing shape you like, maybe did more math, maybe did some CAD, now it’s time to build something. Let’s look back at that wing shape, you found a perfect NACA (blah blah) wing for the plane. It has got a good stall speed, smooth aerodynamics, high lift-to-drag ratio, now how the heck do you build it? (Below the steps is a tips/tricks that we learned from our year.)

Well, there are a few fabrication options you have, lucky you! Most of them have the same general flow it just depends on what you want materials you want to use.

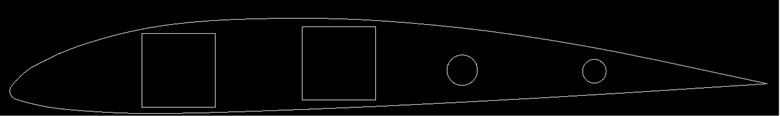

Step 1: Get your airfoils into a converter or somehow get them into CAD. From there add the correct wing spar details you want for your specific plane. There are several images online of examples, below is one of ours using the carbon fiber I-beams.

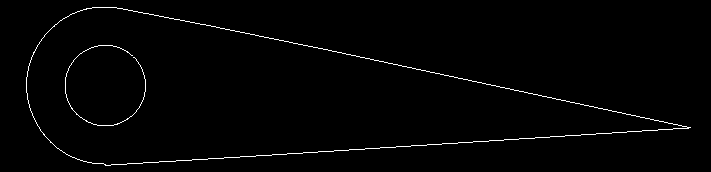

Step 2: Also have a file for your control surfaces and cut those out as well. Below is an example of one we used for the wing. The hole is where the back spar would run though and attach to the rest of the wing formers.

There are different converters you may need to use and a software system to run the laser cutter, there is another file in the DBF teams that shows step-by-step how to use it if you are confused!

Another thing to watch for is how many formers you want to use. The fewer formers the less rigidity of the wing, too many and the wing may break under any deflection.

Step 3: Once they are in CAD make them into a DXF file, and use the laser cutter to cut them out, the formers are generally made from wood or foam. Foam is good for quick prototyping, but busla/basswood is really good for actual form and strength.

Step 4: Gather the materials for the Spars and lay them out accordingly, making a small mark where each of the former should go.

Step 5: GLUE, GLUE, GLUE! Glue the formers into place. And be sure they are in place.

Step 6: Make sure there is a spot for the servos that are going to control the control surfaces (for the tail these servos can be outside of it but that causes drag this is more for the wings though). It is important that these servos are glued into place and ready to go, with wiring that goes outside the wing BEFORE you close the wing. Be sure to check the servo works and any extra extension wires work as well to save a lot of headaches. And glue the servo to the respective spot!

Step 7: Afterwards, use the appropriate method for creating the wing shape. If you are using monokote for the wings:

- Cut out the piece needed for the monokote

- Peel the back off for the sticky side

- Use the hot iron to stick the monokote to the wood (it needs to be wood for monokote

- Then use the heat gun to shrink the monokote

- Boom a nice and sleek wing

If you are using foam board for the wings:

- Cut out the foam piece to the correct size to lay it up

- GLUE the bottom of the formers to the foam and wait for a bit

- GLUE the top of the formers then fold the foam on top of it and wait

- Boom a wing with a sleek surface again

For both of these methods, you will need to cut out the area on the wings for the aileron to go or the flaps again depending on the design. This will be the area where you put your servos at.

Step 8: Do the same process for the alerions and for the tail. Now they are generally smaller so it may be helpful to remove a layer of paper on one side of the foam that will help for the bending of it.

Step 9: Beyond that it is just attaching control horns to the control surfaces with wires to link the servos and control horns together, make sure all servos are at a home position before attaching the wires and it always helps to check servos and control surfaces after building them!!

TIPS/TRICKS:

We learned a lot from this year but here are a few things just to watch out for.

- Make sure to TEST, TEST, TEST the servos and wires!!! We had so much heartache from missing a broken servo early on

- Look at the size of the control surfaces, we missed that on our first prototype and wondered why we couldn’t control the plane at all… yeah it was dumb just don’t be dumb.

- Attaching stuff rigidly is very important because every year there is a wingtip test that can’t have more than 1” deflection of the wing and they are serious about it!

- Try not to neglect sizing problems or wing design if it isn’t working and you need to rebuild one. Fire up the hot glue and rebuild it, it will save problems later (but obviously there is a cut off so there is a point of cutting losses and just getting it done)

- I cannot stress enough once again there are many videos and resources out there that can help with making the wings or making them stronger, use them to your advantage to at least get ideas rolling.

In conclusion of this entire paper/ website. This is a living document/ website that should be changed and modified as more teams learn more stuff. I think we could have a winning DBF team each year if we keep passing knowledge on. So here is the start, keep adding and passing it!