Intro The goal of this guide is to provide a straightforward, formulaic method for determining the optimal airfoil choice for a given aircraft. This is a process beginning with the aircraft’s mean aerodynamic chord, wingspan, aircraft cruise speed, and required wing thickness. The end result is an airfoil profile that can be manufactured. This was … Continue reading DBF Airfoil Optimization

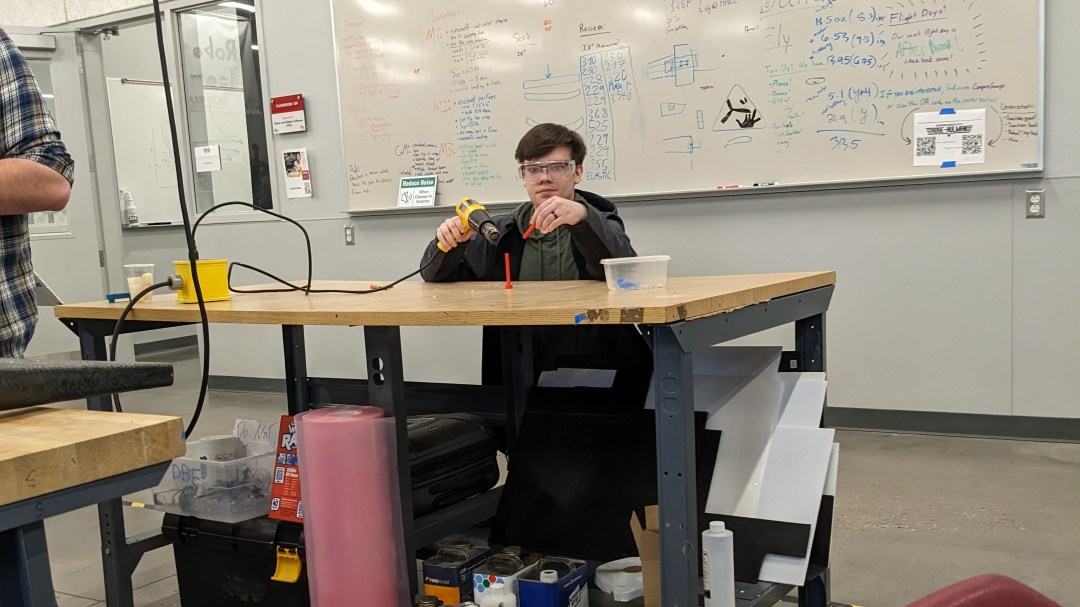

DBF Aircraft Component Fabrication

External Author – JJ Lay Note that this tutorial is not my own work, but was developed by the adorable JJ Lay and is hosted here for convenience. Landing Gear This is more important than you think it is. We talked about doing a drop test all year of just about a 1ft. and now … Continue reading DBF Aircraft Component Fabrication

DBF “The Spreadsheet” Aircraft Design

External Author – Preston Boling Note that this tutorial is not my own work, but was developed by the extravagant Preston Boling and is hosted here for convenience. Download default-spreadsheetDownload Introduction The ‘spreadsheet’ as it is affectionately dubbed by the capstone team as well as anybody who has taken ME461 (Aircraft Design), is the blueprint … Continue reading DBF “The Spreadsheet” Aircraft Design

DBF Choosing Materials for a Model Aircraft

External Author – Patrick Hottle Note that this tutorial is not my own work, but was developed by the reasonably rational Patrick Hottle and is hosted here for convenience. Intro There are five primary material types that DBF (Design-Build-Fly) uses when fabricating RC planes. Foam (foam board, polystyrene) Wood (balsa, basswood, etc.) Composites (fiberglass, carbon … Continue reading DBF Choosing Materials for a Model Aircraft